I have been turning my attention recently to improving the usability and intuitiveness of the design for Production Line. I run some ads to promote the game, and have to assume a bunch of people buy it and play it without ever seeing me or anyone else play it in a video, have not read about it anywhere, and are relying purely on the in-game tutorial. Of course tutorials are all well-and-good, but ultimately the aim has to be to have a game design and GUI so intuitive that it just feel obvious to the player and they don’t get frustrated or stuck.

The next update (1.31, coming tomorrow with any luck), comes with a whole bunch of cool usability improvements. Supply stockpiles and new car designs now copy all existing options, which makes them much more useful features. there are some pricing and production hints on the sales matrix, and a host of other things. I have identified 2 small areas that I think are still confusing and want to improve upon…

The first is the interface for choosing which cars to produce. Basically the game starts with just one design, and only when you have created extra models do you need to worry about this. To edit the ‘production schedule’ you need to go the the slot at the very start of the production line (there may be several lines), click it to launch its details screen, and then notice the new button that gives you access to this feature (which is then relatively well explained).

There are several problems here:

- The player may not even realize they need to do this, and assume the cars are equally produced.

- The player may have no idea where the start of their line is, at first glance.

- The player may not spot the new button even if they do click on the start of the line.

There are a bunch of solutions to this. Firstly, I could stick a big fat warning on the car design window, along with a new stat showing production last hour, alerting the player to the fact that no production of this car is currently scheduled. Maybe add a tooltip on there explaining what to do to get to the production schedule screen?

Secondly, I could have a permanent icon floating above the start of the line indicating this is where the production scheduler is, and maybe double up as a button that launches the scheduler for that slot.

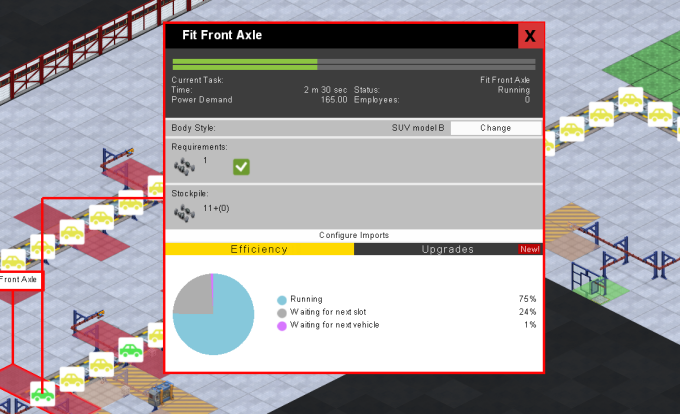

Thirdly maybe I need something more obvious than just a text button, something with icons, and which draws the players eye much more on that slot window? Just a button with ‘Change’ on it is kinda awful :D

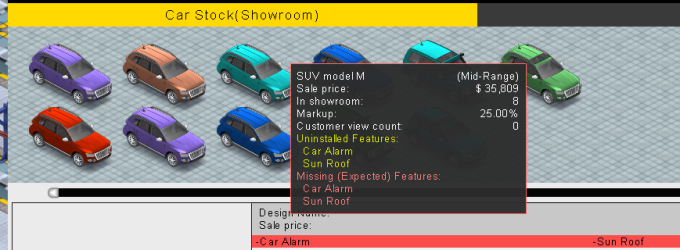

Thats just the first usability issue. The second is a problem relating to missing features on cars, something that is very badly communicated to the player. The player selects which features should be applied to each of their various car designs, with some getting tons of them, and cheaper models getting few. This means that at a slot such as ‘fit wheels’ some cars will get alloy wheels, some will not. Thats fine, but sometimes the player gets out of synch, and researches the ‘alloy wheels’ tech, applies it to some designs, and then forgets to upgrade all the slots that fit wheels. (Or at least all the ones the expensive cars go through). We currently have yellow text in the showroom for cars which have ‘missing’ features, but it makes absolutely no distinction between features missing because the cars production pre-dated this feature (old stock), and ones where there was a screw-up and a feature got missed.

Ideally the screw-up should never happen, but I’m wary of stopping the whole line when this happens. That may be confusing, and will need explanatory GUI anyway. However, it may be the best option. I could reserve that yellow text just for stuff which was really missed, and maybe leave it in white or labelled differently for stuff which is just ‘old stock’. That would at least distinguish between the two. I guess I could also have a popup on the vehicle as it goes around the factory to show a missing feature, so the player notices this before it gets as far as the showroom (by which time many poorly-configured cars have been made).

I’m still musing on the best solution to this.

A heads-up on future stuff. I will ship 1.31 this week, then I’m away for a week from Sunday, and just after that will have a booth at the EGX show in the Birmingham NEC in Birmingham UK. Please do come along if you can and say hi, or try the game (if you dont already have it). press interviews most welcome!

I guess I should point out to any new readers that Production Line is in Early Access on steam/GoG and direct from us. its $15.99 and you can grab a DRM-free copy, together with a steam key from the link below…